Feeding the world, saving the planet

How a Macquarie SynBio spinout is leading a green agriculture revolution.

First published on Macquarie University

Cattle and sheep are major contributors to global warming, thanks to their digestive processes spewing millions of tonnes of methane into the atmosphere each year. Against a backdrop of mounting food security pressures and ever-increasing global demand for meat and dairy products, the solution is far more complex than simply eating less meat. But according to Number 8 Bio CEO and Co-Founder Dr Tom Williams, the answer could lie in the incredible potential of synthetic biology technologies.

“There are about 2.6 billion cattle and sheep on Earth, and the methane emissions they produce are responsible for somewhere between 6 and 10 per cent of climate change,” Dr Williams explains.

“These emissions also decrease the productivity of the animals because some of the feed they eat – rather than being absorbed to enable them to grow or make wool or produce milk – is effectively lost to methane in the atmosphere. By shutting this down, we can not only eliminate carbon emissions, but also enhance agricultural productivity, decreasing the cost of animal feed by around 10 per cent in the process.”

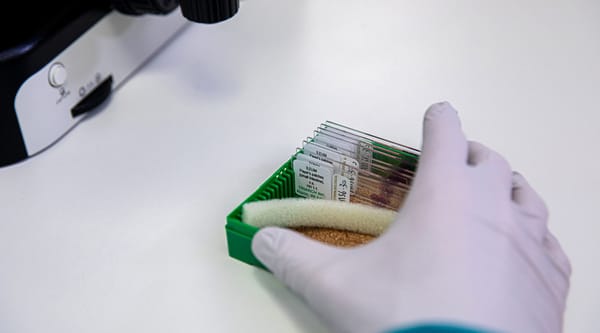

Launched in 2022, Number 8 Bio is harnessing the power of synthetic biology to decarbonise the agricultural sector, engineering microbes to create agricultural feed capable of reducing ruminant methane emissions in livestock. Dr Williams and his co-founder Dr Alex Carpenter, who is Chief Scientific Officer at Number 8 Bio, began ideating the company in 2019 after reading about a seaweed-based feed additive able to eliminate methane emissions from cattle. This was a brilliant discovery but problematic to deliver at scale, and the pair saw an angle for a new technology.

“Synthetic biology is a way of customising, enhancing and scaling what’s found in nature for human benefit – we’ve taken what the seaweed is doing in terms of active molecule production and transported that into scalable microbes like yeast,” Dr Williams says.

“The technology underlying our products is unique, effective and scalable. It uses microorganisms feeding on renewable carbon to produce food; essentially, we’re producing a dried baker’s yeast that can be added to animal feed to prevent methane emissions, improve productivity and enhance the health of the animals.”

The innovative deep tech startup was spun out of Macquarie’s groundbreaking Australian Genome Foundry (AGF), an automated miniaturised robotic genetic engineering facility, and the ARC Centre of Excellence in Synthetic Biology, both centrepieces of the university’s research led by Distinguished Professor Ian Paulsen. Number 8 Bio has since expanded to encompass a variety of approaches to decreasing methane emissions and improving productivity in cattle: the team is also advancing the use of gas fermentation technology to transform the world’s agricultural systems by creating microorganisms that feed on methane or carbon dioxide and decrease the need for arable land, fertiliser and water use that comes with growing crops for animal feed. The potential for impact as our climate heads towards a tipping point is immense.

Dr Williams joined Macquarie as a postdoctoral research fellow in Professor Paulsen’s lab in 2015, and has since worked on a range of transformative synthetic biology projects, including the global Yeast 2.0 consortium. He was pivotal in developing and realising the Foundry, serving as its Chief Scientific Officer and playing a key role in growing the University’s leadership in this space. In turn, the support he found within Macquarie’s synthetic biology and innovation ecosystems – the facilities and practical help for research commercialisation and impact – have been vital in taking Number 8 Bio from bright idea to a thriving commercial entity.

“We ideated the company at the ARC Centre and our scientific staff are incubated at the AGF, where they have access to world-class equipment in a combination that is unique within Australia and probably quite rare internationally,” Dr Williams explains.

“The speed at which we can iterate is pretty phenomenal when compared to how long it would take if we were to outsource – the cost and the amount of time would likely have increased tenfold. We can build and test things quickly and cut R&D time substantially, all well within our funding runway, and that’s a massive advantage. We’ve also benefited from the expertise of the Foundry scientists and other incubating companies, and from tapping into Macquarie’s incubation and acceleration ecosystem to get the company set up and off the ground.”

Dr Williams has recently stepped away from his tenured academic role at Macquarie to focus his attention full-time on Number 8 Bio, embarking on its next stage of growth with pre-seed funding of $1.7-million and a move to Macquarie’s newly established DeepTech Incubator. It’s a massive leap for a young researcher who was well on his way to a promising future in academia, but it’s a risk he says has opened up a new and exciting path for research impact.

“I believe I can have a bigger impact as a startup founder commercialising this research. Though my academic lab was well funded, it doesn’t compare to the amount of funding a startup can receive and the scientific resources you can access, enabling you to focus fully on developing scalable commercial solutions to global challenges.”

Macquarie’s Pro Vice-Chancellor (Research, Innovation and Enterprise) Professor Dan Johnson says the University is pleased to be able to support this new generation of entrepreneurial researchers to translate their ideas into a commercial setting and achieve impact.

“Macquarie University researchers address many of the big, important questions facing the world, and their contributions to date have had far-reaching consequences, translating into real improvements for local, national and global communities,” Professor Johnson explains.

“Number 8 Bio has, and will continue to be, incubated within the University environment, culture and systems. We hope it will scale and make a meaningful contribution to decarbonisation efforts in the livestock sector.”