Cutting the costs of solar

ANU has been awarded funding for research into technologies that reduce the cost of solar energy for Australians.

First published by ANU College of Engineering, Computing & Cybernetics

The Australian National University (ANU) has been awarded more than $9 million in funding from the Australian Government for research projects to reduce the cost of solar energy for Australians.

The investment from the Australian Renewable Energy Agency (ARENA) supports ultra low cost solar research and development (R&D), as well as the next phase of commercialisation activities to help get the new technologies into the market.

ARENA has set a target for Solar 30/30/30, which aims to improve solar efficiency to 30 per cent and reduce the cost of solar modules to 30 cents a watt by 2030.

Three major research projects led by the ANU College of Engineering, Computing and Cybernetics will be supported by ARENA. They each focus on ways that we can improve technologies to meet this target and drive the cost of solar even lower for both Australian industry and consumers.

We spoke to the lead investigators to find out more about their work, and how it will contribute to the rise of renewable energies in Australia.

Stacking up the savings

Project name: ANU, Canberra, Stream-1, Cost-effective Si/perovskite tandem modules on passivating contact Si cells

ANU lead chief investigator: Professor Klaus Weber

Additional ANU chief investigators: Professor Kylie Catchpole, Professor Daniel MacDonald, Dr Heping Shen, Dr Pheng Phang

This project aims to develop tandem solar cells and modules to the point of commercial production.

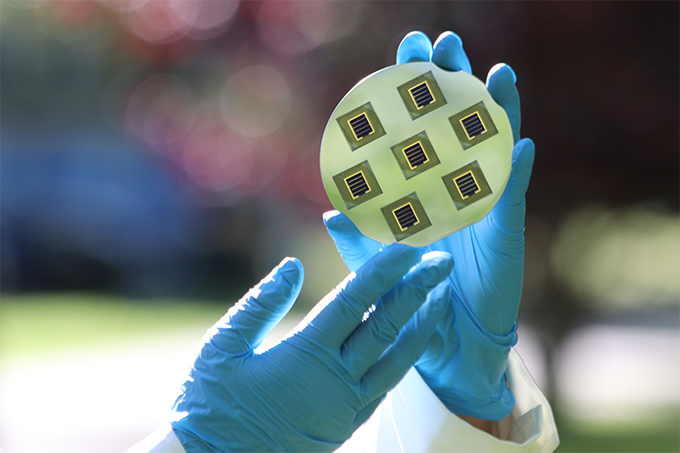

The tandem cells consist of two solar cells – perovskite and silicon – stacked on top of each other. By using a combination of different materials with different properties, the tandem stack can more efficiently convert sunlight to energy than a regular solar cell.

The ANU-led project is a five-year joint venture with partners at Jinko Solar, one of the world’s foremost solar module manufacturers, and research teams at UNSW and University of Melbourne.

“This project will contribute to accelerating the global transition away from fossil fuels and towards clean energy,” says lead chief investigator Professor Klaus Weber.

“Photovoltaics, or solar cell technology, is the fastest growing energy technology globally, far outstripping fossil fuel generation like coal and gas. However, given the urgency of lowering greenhouse gas emissions, even this rapid growth rate needs to be stepped up.

“We will see massive further growth in photovoltaics (PV) production and installation in the coming decades. To accelerate this growth, the cost must be as low as possible.”

With this goal in mind, researchers are looking for solutions such as tandem cells, that would allow solar generated electricity to be used cheaply for a wide range of tasks. This includes generating clean hydrogen and ammonia, which is needed to clean up other industries such as iron and steel production.

“A reduction in the cost of PV electricity will help to accelerate the uptake of renewables in Australia,” says Professor Weber.

“This will be particularly helpful given ambitious plans to export solar energy – either directly via high voltage transmission lines to our neighbours – or via the generation of solar fuels such as hydrogen and ammonia.”

School of Engineering researcher Dr Heping Shen poses with a tandem solar cell in the PV laboratories at ANU.

Keeping the heat on

Project name: Low-cost integration of on-site PV for large-scale industrial heat supply

ANU lead chief investigator: Associate Professor Joe Coventry

Additional ANU investigators: Professor Andrew Blakers, Associate Professor John Pye, Dr Ahmad Mojiri

This project aims to progress the technologies behind industrial heating, swapping to a renewable source that won’t further warm our planet in the process.

The team will develop a direct electrical heating (DEH) technology, where the current from a photovoltaic (PV) system is passed directly through a resistive device, without a conventional inverter. The model uses “behind-the-meter” solar PV as its energy source, located on the rooftop or close by the industrial facility. This costs significantly less, thanks to major savings in the electrical components. There are no multi-stage converters, no transformers, and no transmission lines required downstream of the solar PV.

This behind-the-meter PV DEH enables low-cost thermal energy storage, estimated at 8-12 times cheaper than battery or pumped-hydro storage.

“The concept offers an alternative to conventional gas heating for business,” says lead chief investigator Associate Professor Joe Coventry.

Approximately 42 per cent of Australia’s total energy consumption is by industry, of which 51 per cent is from process heat. Most of this demand is supplied by fossil fuels, especially for high temperatures above 150°C where fuels contribute 11.3 per cent of Australia’s greenhouse gas emissions.

The technology being developed in this project would bring down the cost for companies to switch to solar heat.

“Reducing balance-of-system costs for PV direct heating technology opens up a huge potential decarbonisation market,” says Associate Professor Coventry.

Renewable electricity only accounts for 1.1 per cent of the global industrial process heat demand in 2020. Direct electrification can play a major role in global industrial decarbonisation, including meeting up to 78 per cent of Europe’s industrial energy requirements.

The team of ANU researchers have partnered with RMIT University as well as industry partners Graphite Energy, Fortescue Metals Group and Visy, to develop, build, and test the new PV DEH technology.

Its commercial readiness would then be scoped through two industrial pilots: targeting the heat supply at an iron-ore beneficiation facility in the Pilbara, Western Australia, and at a wastepaper recycling plant in Coolaroo, Victoria.

This project supports several early career researchers and students, building skills and capability in the solar energy field. ANU is offering two PhD scholarships to work on this project. If you’re interested, please contact Associate Professor Joe Coventry to find out more about the opportunities.

- PhD scholarship for decarbonising industry: direct electrical heating using behind-the-meter PV

- PhD scholarship for decarbonising industry: thermal storage of heat generated from behind-the-meter PV

Next gen technology

Project name: Next generation low-cost silicon solar cells above 26 per cent efficiency in mass production

ANU lead chief investigator: Professor Daniel MacDonald

Additional ANU investigators: Dr Di Kang, Dr Marco Ernst, Dr Pheng Phang

This project aims to increase the efficiency of silicon solar cells, by applying new materials to make electrical contact to the underlying silicon wafers.

Silicon solar cells currently make up about 95 per cent of the global market, so any performance improvements would have a significant impact in the real world.

The research team have partnered with one of the world’s largest solar module manufacturers, Jinko Solar, to put these ideas to the test.

“We plan to transfer this technology to solar cell production lines at our industry partner Jinko Solar, leading to cell efficiencies above 26 per cent,” says lead chief investigator Professor Daniel MacDonald.

“This will increase the amount of electricity that each solar module can generate, therefore reducing the cost per unit of electricity.”

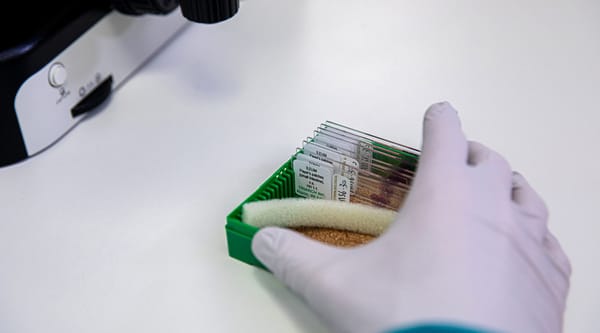

This next-generation research will take place in the PV laboratories at the ANU School of Engineering. The most promising ideas will be transferred to the pilot lines at Jinko Solar, where they can assess their suitability for mass production.

“By helping to reduce the cost of solar modules, this project will make it cheaper for Australians to put solar on their rooftops, and for Australian companies to build large-scale solar farms,” Professor MacDonald says.

“We have to keep reducing the cost of solar electricity so that we can replace fossil fuel electricity generation more quickly. Of course, this also requires new storage and transmission infrastructure, but cheaper solar modules are a critical part of the energy transition.”